- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Pinch Valve

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

High resilience rubber liners with rubber boss, no leakage Smooth internal surface makes slurry flow stably and fast without flow resistance The rubber elasticity exceeds 80%, the slurry will not cause water hammer impact. Valves liners have strong anti fatigue ability, longer service life Easy to replace, simple structure and convenient operation High resilience rubber spool, more flexible and reliable opening and closing

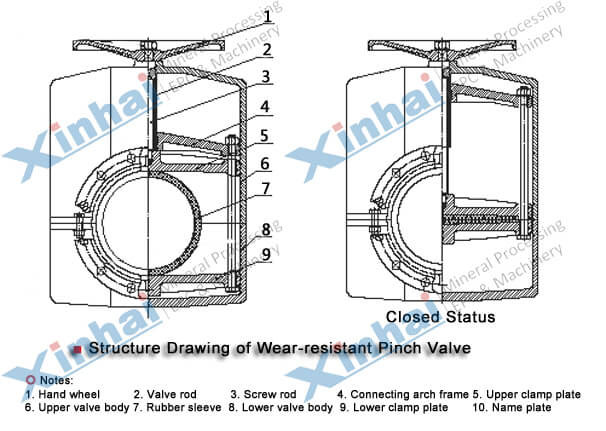

【Product Structure】

Wear-resistant Pinch Valve is composed of upper grip, valve body, rubber spool and lower grip

【Technical Parameters】

| Specification | D | B | C | A | E | F | G | Standard Flange | Weight (kg) | |||

| Flange Diameter | Bolts PCD | Bolts Diameter | Al | Iron casting | ||||||||

| 20 | 20 | 144 | 150 | 15 | 119 | 80 | 100 | 105 | 75 | 4-Φ14 | 1.6 | 2.8 |

| 25 | 25 | 159 | 165 | 15 | 119 | 90 | 125 | 115 | 85 | 4-Φ14 | 2.3 | 3.2 |

| 40 | 40 | 199 | 205 | 17 | 119 | 118 | 162 | 140 | 100 | 4-Φ18 | 3.5 | 5.5 |

| 50 | 50 | 229 | 235 | 17 | 220 | 156 | 185 | 150 | 110 | 4-Φ18 | 6.5 | 12.5 |

| 65 | 65 | 299 | 305 | 17 | 220 | 190 | 200 | 165 | 125 | 4-Φ18 | 8.8 | 15 |

| 80 | 80 | 309 | 315 | 21 | 220 | 202 | 225 | 185 | 145 | 4-Φ18 | 10.5 | 22 |

| 100 | 100 | 354 | 360 | 25 | 220 | 247 | 269.5 | 200 | 160 | 8-Φ18 | 18.2 | 41 |

| 125 | 125 | 419 | 425 | 28 | 280 | 310 | 350 | 220 | 180 | 8-Φ18 | 29 | 66 |

| 150 | 150 | 479 | 485 | 29 | 280 | 343 | 373 | 285 | 240 | 8-Φ18 | 42 | 99 |

| 200 | 200 | 594 | 600 | 30 | 280 | 457 | 486.5 | 340 | 295 | 8-Φ22 | 87 | 230 |

【Successful case】

An Indonesian mineral processing plant chose pinch valve to control the opening and closing of channel, but its corrosion resistance and impermeability always been troubles. After on-the-spot investigation, Xinhai technical personnel added wear-resisting rubber inside tube valve, effectively avoiding the acid resistance, alkali resistance and corrosion resistance. In the operation process, pinch valve can last half a year without replacement, effectively solved the customer problems.

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China