- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Wear-Resistant Slurry Pump

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Wear – resistant rubber as liners prolongs the service life by 2-4 times Internal rubber liners with small specific gravity can effectively improve the impeller speed;

Maximum flow rate than other slurry pump can improve the efficiency of the whole 10-20%, overall efficiency increased more than 30%;

Small specific gravity wet parts, convenient maintenance, low noise; reduce the number of repair personnel and the operational maintenance cost Smooth wet parts make operation more stable.

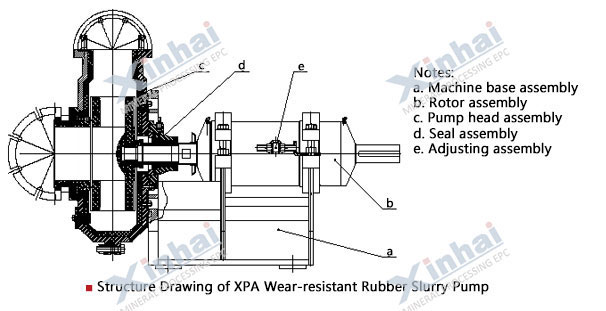

【Product Structure】

The main components of wear-resistant slurry pump includes impeller, motor, sheath etc. Sheath and impeller is made of Xinhai wear resistant rubber. The auxiliary suspenders simply remove the pump shell, and are convenient for maintenance.

【Technical Parameters】

| Model & Spec. | Flow (m3/h) |

Max. Head (m) |

Rotating Speed (r/min) | Max. Rated Power (kW) | Max. Efficiency (%) |

Impeller Diameter (mm) |

Weight (kg) |

Overall Dimension (mm) |

| XPA 50/50 | 20 ~60 | 38 | 800~2400 | 22 | 51 | 200 | 156 | 725X482X491 |

| XPA 80/80 | 30~100 | 45 | 600~2100 | 45 | 53 | 256 | 326 | 915X590X595 |

| XPA 100/100 | 60~160 | 50 | 600~1600 | 75 | 57 | 340 | 440 | 999 X 648 X 660 |

| XPA 150/125 | 100~260 | 47 | 400~1400 | 110 | 63 | 372 | 608 | 1280X736X758 |

| XPA 200/150 | 160~450 | 47 | 450~1200 | 132 | 69 | 433 | 736 | 1313X788X822 |

| XPA 250/200 | 300~900 | 46 | 400~1200 | 250 | 78 | 454 | 1250 | 1600X812X956 |

| XPA 300/250 | 400~1500 |

45 | 300~900 | 600 | 73 | 610 | 1956 | 1698X966X1083 |

【Successful case】

A gold processing plant in Shandong concentrator, the pulp temperature is very high after mineral processing, after applied common slurry pump, the equipment damage rate is extremely high so that the processing cost is heavy. Searching through the network, the client contacted with Xinhai Mining, the technical personnel recommended to adopt XPA wear-resistant rubber slurry pump. The device inherited the advantages of the original slurry pump, its good flexibility has good cushioning effect on the slurry impact, the pulp temperature can be adapt to-40˚C∼+70˚C, and the customers are very satisfied with it.

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China