- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Double Stages Slurry Pump

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Break through the head limit (60 meters) of rubber pump, up to 70 meters;

Impellers and casings lined with Xinhai No. 35 high wear-resisting rubber, the life is 2-4 times longer than the life of metal pump;

The rubber slurry pump with resistance to wear and corrosion and high head;

Packing sealing, simple and reliable, no leakage.

It is easy to replace wet parts

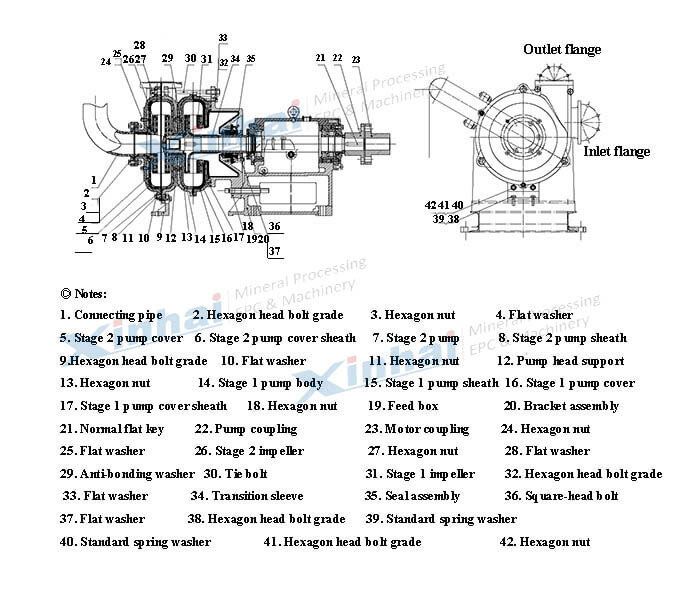

【Product Structure】

The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are backpitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With simple structure, higher operation rate, and rolling bearing, the energy conservation is significant.

【Technical Parameters】

| Items Model |

Rotation Speed (r/min) |

Flow (m3/h) |

Head (m) |

Max shaft power (KW) |

Referenced motor (KW) | |

|---|---|---|---|---|---|---|

| Model | Power | |||||

| XPA(2)-50 | 1480 | 27.5 | 76.0 | 22.3 | Y225S-4 | 37 |

| 1480 | 41.4 | 72.2 | 22.3 | Y225S-4 | 37 | |

| 1480 | 55.2 | 66.1 | 22.3 | Y225S-4 | 37 | |

| 1480 | 69.0 | 56.0 | 22.3 | Y225S-4 | 37 | |

| 1480 | 80.0 | 43.5 | 22.3 | Y225S-4 | 37 | |

| XPA(2)-65 | 1480 | 40.0 | 76.0 | 32 | Y225M-4 | 45 |

| 1480 | 60.0 | 72.2 | 32 | Y225M-4 | 45 | |

| 1480 | 80.0 | 66.1 | 32 | Y225M-4 | 45 | |

| 1480 | 100.0 | 56.0 | 32 | Y225M-4 | 45 | |

| 1480 | 115.0 | 43.5 | 32 | Y225M-4 | 45 | |

| XPA(2)-75 | 1480 | 56.0 | 73.3 | 49 | Y250M-4 | 55 |

| 1480 | 85.0 | 69.0 | 49 | Y250M-4 | 55 | |

| 1480 | 113 | 62.5 | 49 | Y250M-4 | 55 | |

| 1480 | 150 | 51.2 | 49 | Y250M-4 | 55 | |

| 1480 | 169 | 44.0 | 49 | Y250M-4 | 55 | |

| XPA(2)-100 | 1480 | 70.0 | 73.5 | 62.5 | Y280S-4 | 75 |

| 1480 | 105 | 71.6 | 62.5 | Y280S-4 | 75 | |

| 1480 | 140 | 68.6 | 62.5 | Y280S-4 | 75 | |

| 1480 | 186 | 61.9 | 62.5 | Y280S-4 | 75 | |

| 1480 | 245 | 48.5 | 62.5 | Y280S-4 | 75 | |

| XPA(2)-100-Ⅰ | 1480 | 79.7 | 80.0 | 78.2 | Y280M-4 | 90 |

| 1480 | 119 | 78.0 | 78.2 | Y280M-4 | 90 | |

| 1480 | 159 | 74.8 | 78.2 | Y280M-4 | 90 | |

| 1480 | 211 | 67.5 | 78.2 | Y280M-4 | 90 | |

| 1480 | 279 | 52.9 | 78.2 | Y280M-4 | 90 | |

| XPA(2)-100-Ⅱ | 1480 | 58.0 | 91.8 | 64.7 | Y280M-4 | 90 |

| 1480 | 87.0 | 89.1 | 64.7 | Y280M-4 | 90 | |

| 1480 | 116 | 85.7 | 64.7 | Y280M-4 | 90 | |

| 1480 | 154 | 77.3 | 64.7 | Y280M-4 | 90 | |

| 1480 | 203 | 60.6 | 64.7 | Y280M-4 | 90 | |

【Successful case】

An iron ore plant in Sudan needs a pump to push slurry into the pump box before pulp stirring. At first, the slurry pump head that plant selected before can only be up to 50m, which still cannot reach the height of the pump box. After learned the products details by Xinhai website, the customers purchased Xinhai XPAⅡhigh head wear-resisting rubber slurry pump. This device adopts double impeller series set, the head is as far as 70m, and combined with Xinhai wear-resisting rubber, the service life is as2-4 times as metal high head slurry pump, saving a lot of cost for the plant.

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China