- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Autogenous Mill

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Simplify the crushing and grinding process; feeding particle size is 200-350mm, and after the first autogenous grinding, the product particle size reaches below a few millimeter.

It is suitable for ore with high content of mud and water; small area taken, low investment

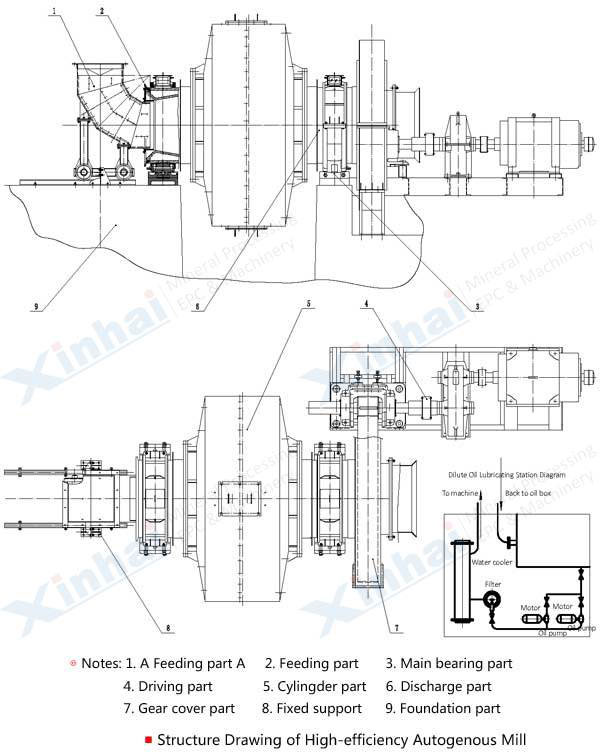

【Product Structure】

Except for few hard ore, most of metal ores could use wet autogenous mill.

【Technical Parameters】

| Model | Diameter (mm) | Length (mm) | Feed Size (mm) | Main Motor | |||

| Model | Power (kW) | Voltage (V) | Weight (t) | ||||

| ZMJ4014 | 4000 | 1400 | < 350 | JR148-8 | 245 | 10000 | 75 |

| ZMJ4018 | 4000 | 1800 | < 350 | JR1410-8 | 320 | 10000 | 82 |

| ZMJ5518 | 5500 | 1800 | < 400 | TDMK800-36 | 800 | 10000 | 175 |

| ZMJ6522 | 6500 | 2200 | < 400 | TDMK1600-40 | 1600 | 10000 | 280 |

| ZMJ7525 | 7500 | 2500 | < 400 | TM2500-16 | 2500 | 10000 | 455 |

| ZMJ7528 | 7500 | 2800 | < 400 | TM2500-16 | 2500 | 10000 | 465 |

【Successful case】

In Vietnam iron ore dressing plant, the ore capacity is larger, and the auxiliary equipment under the cost control has a small quantity. In this case, Xinhai efficient autogenous mill solved these problems effectively. Xinhai efficient autogenous mill can achieve two and three stage crushing, part or all crushing of ball mill and rod mill, it is suitable for the coarse grinding after coarse crushing. Finally, in the actual production, Xinhai efficient autogenous mill improved production efficiency, controlled the cost in the operation, the customer is very satisfied with the result.

【Related knowledge】

- The Prosperity of Iron Processing Equipment Markets

- “Green Road" of Mines Developing---Tailings dry stacking

- Characteristics introduction of the various components of vibration screen

- Mineral Processing Test and Study on Feldspar in Albania

- Seven Tips Increasing Ball Mill Grinding Efficiency

- Iron Ore Tailings Re-Processing Technology

- How the Copper Flotation Process Enhances Ore Recovery and Profitability

- How Hard Rock Lithium Processing Works: Mine to Market

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China