- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Overflow Type Ball Mill

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Jack-up device, easy maintenance;

The hydrostatic and hydrodynamic bearings ensure the smooth operation;

Low speed transmission is easy for starting and maintenance;

The oil-mist lubrication device guarantees reliable performance of bearings;

The gas clutch adopts the flexible start-up model.

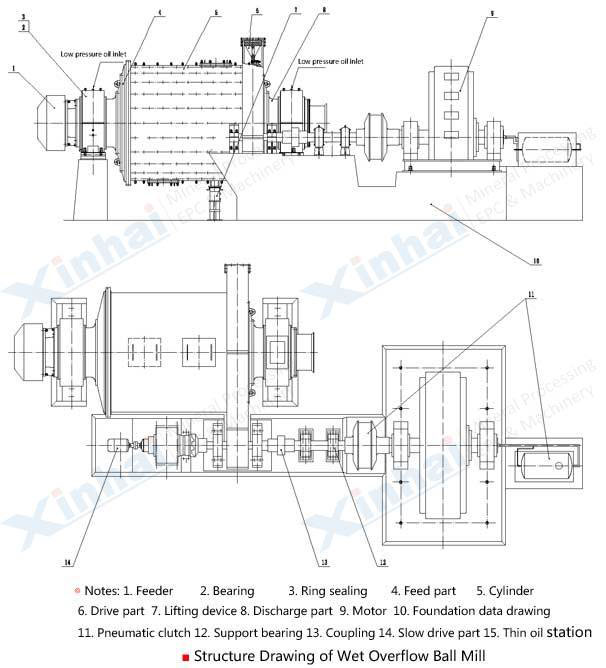

【Product Structure】

Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are backpitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With simple structure, higher operation rate, and rolling bearing, the energy conservation is significant. Generally used in the grinding of ores with finer fineness.

【Technical Parameters】

| Model | Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model | Motor Power (kW) |

Length (mm) |

Width (mm) |

Height (mm) |

Effective Volume (m3) |

Max. Ball Load (t) | Weight (kg) |

| MQY0918 | 900 | 1800 | Y225M-8 | 22 | 5080 | 2300 | 2015 | 0.9 | 1.66 | 6078 |

| MQY1212 | 1200 | 1200 | Y225S-8 | 18.5 | 5788 | 2994 | 2540 | 1.14 | 2.4 | 11473 |

| MQY1224 | 1200 | 2400 | YR280S-8 | 55 | 6112 | 2794 | 2540 | 2.28 | 3.8 | 12308 |

| MQY1515 | 1500 | 1500 | JR115-8 | 60 | 5766 | 2945 | 2600 | 2.2 | 6.4 | 15424 |

| MQY1530 | 1500 | 3000 | JR125-8 | 95 | 7979 | 2945 | 2600 | 5 | 10 | 18690 |

| MQY2122 | 2100 | 2200 | JR128-8 | 155 | 8070 | 4840 | 3795 | 6.6 | 14 | 47800 |

| MQY2130 | 2100 | 3000 | JR137-8 | 210 | 8870 | 4840 | 3795 | 9 | 20 | 47220 |

| MQY2136 | 2100 | 3600 | JR137-8 | 210 | 9300 | 4840 | 3795 | 10.8 | 22 | 52010 |

| MQY2145 | 2100 | 4500 | JR148-6 | 310 | 11029 | 4738.6 | 3300 | 13.5 | 23.8 | 58305 |

| MQY2430 | 2400 | 3000 | JR1410-8 | 280 | 9710 | 4778 | 4120 | 12.1 | 23 | 65880 |

| MQY2721 | 2700 | 2100 | JR1410-8 | 280 | 9400 | 5600 | 4700 | 10.7 | 24 | 63900 |

| MQY2736 | 2700 | 3600 | TDMK400-32 | 400 | 13049 | 5800 | 4680 | 17.8 | 32 | 96570 |

| MQY2740 | 2700 | 4000 | TDMK400-32 | 400 | 11850 | 5667 | 4496 | 20.4 | 40 | 78800 |

| MQY3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6760 | 5150 | 21.4 | 45 | 107660 |

| MQY3245 | 3200 | 4500 | TDMK630-36 | 630 | 14356 | 7200 | 5152.5 | 32.8 | 65 | 130283 |

| MQY3254 | 3200 | 5400 | TM1000-36/2600 | 1000 | 15800 | 6760 | 5200 | 37.2 | 73 | 121000 |

| MQY3645 | 3600 | 4500 | TM1000-36/2600 | 1000 | 15000 | 7200 | 6326 | 41.8 | 76 | 135000 |

| MQY3650 | 3600 | 5000 | TM1250-40/3250 | 1250 | 17157 | 7755 | 6326 | 46.4 | 86 | 145000 |

| MQY3660 | 3600 | 6000 | TM1250-40/3250 | 1250 | 19000 | 7755 | 6326 | 55.7 | 102 | 154000 |

| MQY3690 | 3600 | 9000 | TDMK1800-30 | 1800 | 28000 | 4600 | 5600 | 83 | 163 | 212000 |

| MQY3867 | 3800 | 6700 | TDMK1600-30 | 1600 | 19000 | 8200 | 7100 | 70 | 130 | 186000 |

| MQY4067 | 4000 | 6700 | TDMK1800-30 | 1800 | 15600 | 9600 | 7300 | 78 | 138 | 207000 |

| MQY4561 | 4500 | 6100 | TDMK2200-30 | 2200 | 18200 | 10500 | 7600 | 93 | 151 | 238000 |

【Successful case】

In the process of Tungsten concentrates original production, the owner adopted grid type ball mill method in two stage grinding process to achieve great capacity. After a period, the client found the production didn’t reach the standard, and the equipment had a serious consumption, so the client adopted Xinhai wet overflow ball mill. The pulp of Xinhai wet overflow ball mill overflow automatically, without forced discharge, which reduces the equipment wear and energy consumption, the discharging particle size is small, the qualified rate of grind size is improved, at the same time costs is under control.

【Related knowledge】

- Green mine is increasingly important

- The key links of CIP gold processing--- gold loaded carbon desorption and washing

- Gold mine tailings, the treasure place of recovery gold

- Xinhai magnetic separation equipment with high efficiency and quality

- Xinhai Mining·Mineral Processing Automatic Control System

- Here are Reasons and Solution for Belt Deviation of Belt Conveyor!

- Affordable Gold Ore Processing Practical Guide for Growing Enterprises

- What machines are used in lithium processing?

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China