- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Home Product Dewatering Machine High Frequency Dewatering Screen

High Frequency Dewatering Screen

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Xinhai Company has many special technical designs in dewatering screen. The main deck of the screen slopes upwards and forms a 45° sloping with the back-deck section. Two vibration motors are installed horizontally. One is installed on the top of the other one. Unbalanced gravity produces rotary effect makes the screen work stably.

Double vibration motor excitation, firm and compact structure, getting rid of thedefectsof traditional eccentric vibrator such as large structure, oil leakage, large wear, large noise, inconvenient repair, etc.

Xinhai wear-resistant rubber lined on the side guard plate of Xinhai dewatering screen protects it from wearing and reduces the pollution of iron.

Xinhai mine dewatering screen uses the Xinhai embedded wear-resistant urethane mesh, its life is 3-10 times longer than the traditional metal mesh’s, and it avoids direct collision of metal frame and ore.

Vibration damper for dewatering screen is used Xinhai rubber damper column, which is more suitable for wet conditions, and is durable.

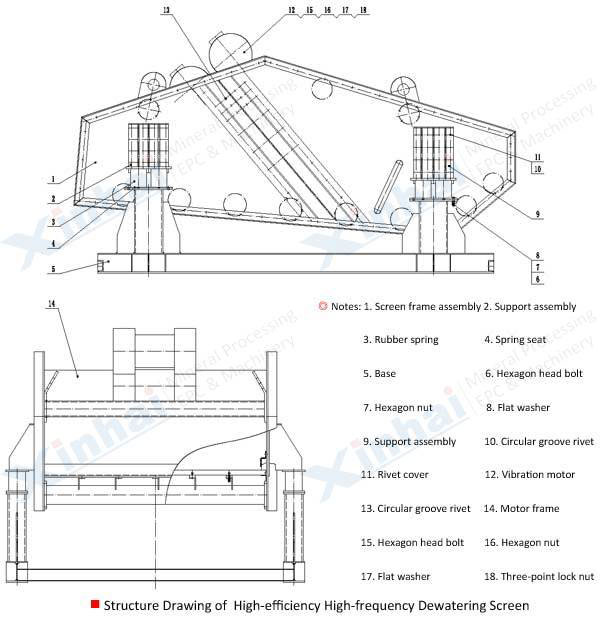

【Product Structure】

The product adopts double vibration motor as power supply: The two motors that rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of straight line, which is for the purpose of dehydration. The screen frame is connected by the high-intensity bolts, so the structure is stable and durable.

【Technical Parameters】

| Model | Min. 30% Solid Feeding Slurry Concentration by Volume | Unit Motor Power (kW) X Quantity (set) | ||||||

| Coal Fine Theoretically -0.5+0.1(mm) Specific Gravity 1.5 | Coarse Sand Approxilly- 5(mm) 100%, -0.6(mm)50%, Specific Gravity 2.7 | Fine Sand 90% -1(mm) Specific Gravity 2.7 | 980 (r/min) | 1460 (r/min) | ||||

| 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | |||

| VD6 | 6~8 | 10 ~13 | 14 | 28 | 10 | 21 | 2 X2 | |

| VD9 | 9~12 | 15 ~20 | 21 | 42 | 16 | 32 | 3X2 | |

| VD12 | 15 ~19 | 24 ~30 | 33 | 67 | 25 | 50 | 2.6X2 | 4X2 |

| VD15 | 30 ~35 | 50 ~60 | 63 | 125 | 47 | 94 | 2.4X4 | 2.25X4 |

| VD18 | 35~45 | 60 ~80 | 77 | 153 | 57 | 115 | 3.7X4 | |

| VD21 | — | 85~100 | — | 225 | — | 164 | 15 | — |

| VD24 | 95~110 | 250 | 190 | |||||

【Successful case】

A gold concentrator in northeast of China, the capacity is large. In order to save money and multi-usage, the client chose Xinhai high frequency dewatering screen. According to customer requirements, technical personnel applied double motor synchronous technology, universal type eccentric block, adjustable amplitude vibration device to improve the dewatering screen, which reduces the damage of motor, and saves money. Compared with previous dewatering screen in operation process, the screen life extended nearly doubled, customers were very satisfied with this result, and reached a long-term cooperation relationship with us.

【Related knowledge】

- 【Xinhai Case】Indonesia 700TPD Gold Pool Leaching Project

- Grid Type Ball Mill VS Overflow Type Ball Mill, How to Choose Them?

- Xinhai hydrocyclone group combines two impossible advantages

- Tailing Dry Stacking,the helper of water saving in mineral dressing

- Mineral Processing Test and Study on Iron Ore in Philippines

- How to Reduce the Wear of Steel Ball in the Ball Mill Machine?

- The Screening Efficiency of Vibrating Screen is Too Low? Are These Five Performance Parameters Correct?

- How the Copper Flotation Process Enhances Ore Recovery and Profitability

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China