- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

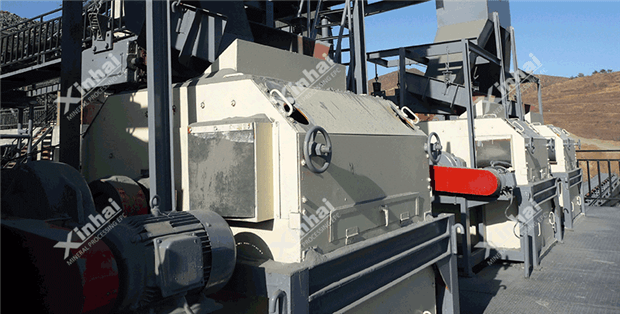

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Home Pruduct News Mining Magnetic Separation

Mining Magnetic Separation

2025-06-30 XinHai Views (9)1.Magnetic Separation Overview & Purpose

Magnetic separators play dual roles in mining. It protects equipment from tramp metal and recovering valuable minerals or removing magnetic impurities from ore

2. Classification of Magnetic Separation

Dry vs wet: Dry units for pre-concentration and equipment protection; wet units for slurry-based recovery .

Magnetic intensity:

Low (e.g., LIMS, drum magnets) for iron ore

High (e.g., rare-earth rolls, induced roll) and high-gradient (e.g., HGMS, matrix) for weakly magnetic minerals

3. Magnetic Separation Types

| Equipment Type | Use Case | Description |

| Overband magnets & head pulleys | Tramp metal removal | Deep fields, installed over belts or in-pulley |

| Drum separators | Iron ore, magnetite | Rotating drum; ferrous sticks to shell |

| Rare-earth roll / induced roll | Dry beneficiation of paramagnetics | Permanent or electromagnetic rolls pull magnetic phases |

| High-gradient / matrix separators | Fine/weakly magnetic minerals | Intense field via matrix to extract fine particles |

| Three-disc high-intensity separators | Special minerals (e.g., tungsten, rare earth) | Adjustable, high-intensity dry units |

| Wet drum separators & electromagnetic filters | Slurry processing | Slurry-fed units for wet magnetic recovery |

4. Magnetic Separation Operating Principles

Tramp metal units use deep magnetic fields to attract and remove ferrous. Ore beneficiation uses shallow or matrix-supported fields to selectively separate based on magnetic susceptibility.

5. Magnetic Separation Target Materials & Applications

Ferromagnetic: Magnetite, nickel, cobalt — recovered by low-intensity units

Paramagnetic: Ilmenite, hematite, tungsten minerals — benefits from high-intensity

Diamagnetic: Impurities like silica are separated out in high-gradient setups

6. Magnetic Separation Design & Operational Choices

| Type | Advantages | Considerations |

| Self-cleaning | Automatically discharges ferrous materials; reduces manual labor | Higher initial cost; more complex structure |

| Fixed (Stationary) | Simpler design; lower cost | Requires periodic manual cleaning |

| Permanent Magnet | Energy-efficient; no external power needed | Magnetic field is constant; cannot be turned off |

| Electromagnetic | Switchable magnetic field; adjustable strength | Higher energy consumption; requires power supply & cooling |

7. Performance Benefits

Enhances plant safety by shielding crushers and conveyors

Increases product purity

Enables fine mineral recovery, even from low-grade ore

Supports sustainability: dry processes without chemicals, lower power use with permanent magnets

8. Customization & Sustainability

Lab test facilities (e.g., Bunting Redditch) enable tailored designs

Modular and digital designs (e.g., Mineral Technologies’ HGMS/LIMS) support scalability and automation

Permanent magnet units can reduce operating costs by 30–50% compared to electromagnets

Magnetic separation is a proven, versatile method supporting both equipment protection and mineral recovery.

Comprehensive Guide to Chrome Ore Beneficiation Technology

Explore the complete chrome ore beneficiation process, including ore types, advanced technologies, and equipment selection. Learn how to improve recovery rates and reduce energy consumption in chrome ore processing.... [more]

No Next

Related Article

- Comprehensive Guide to Chrome Ore Beneficiation Technology

- Chrome Wash Plants: Science, Cost & Regional Insights

- Ball Mill Machine

- What is Lithium Processing Technology

- Mineral Processing Technology

- What are the Technologies for Lithium Production

- Gold Heap Leaching Summery

- How Hard Rock Lithium Processing Works: Mine to Market

- Global Mining Industry Analysis: Trends, Challenges, and Opportunities in 2025

- Phosphate Ore Processing and Beneficiation Plant Design: A Comprehensive Engineering Approach

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China