- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

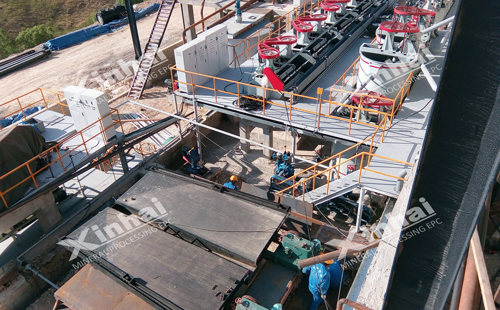

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Comprehensive Guide to Gold Wash Plants

2025-07-21 XinHai Views (13)1. Introduction

Gold wash plants. They're basically these specialized setups that use gravity to snag gold out of loose dirt and gravel. You'll find them in both roll-it-to-the-site and set-it-in-one-spot versions. These things cover everything from a measly 1 ton per hour up to a whopping 500 or more tons per hour.

2.Gold Wash Plant Types and Capacities

Small (1–10 tph): compact, self-contained units ideal for prospectors and small claims.

edium scale (think 20 to 100 tons per hour): you’re looking at mobile setups, all modular, with trommel scrubbers remove the dirt and gravity equipment recovery pulling out the gold. Just practical and portable.

The big (like 100 to 500+ tons an hour): We’re talking massive rigs—rubber tires or tracks—plus some beastly water pumps and conveyor belts that just don’t quit. It’s basically mining on steroids.

3.Gold Wash Plants Core Components

Trommel scrubbers/screens: primary washing and size classification, ideal for clay-laden material

Vibrating screens: optional for low-clay, dry ore feeds

Gravity recovery: sluice boxes, jigs, shaking tables, and centrifugal concentrators

Auxiliaries: feeders, pumps, conveyors, and electric or fuel-powered drives

4. Gold Wash Plants Process Workflow

4.1. Pre-screening: remove oversize rocks

4.2. Scrubbing/Washing: remove clay and fines

4.3. Screening: classify to target sizes

4.4. Gravity Separation: recover coarse and fine gold particles using sluices, jigs, and concentrators

4.5. Final Concentration: often using shaking tables or amalgamation cylinders

5. Gold Wash Plants Recovery Performance

Typical gold recovery ranges from 90–99%, depending on feed quality and equipment configuration. Case examples include a 5 tph mobile plant in Mozambique and a customized 200 tph plant in Ghana achieving high returns

6.Configurations & Design Choices

Modularity: mobile or fixed options; customizable per capacity

Clay handling: choose trommel scrubbers for sticky ore; vibrating screens for drier feeds ([JXSC Machinery][16])

Gravity-only: no chemicals, reliable under varied conditions

7. Applications & Case Studies

Effective in alluvial and vein gold scenarios—from small-scale artisanal operators to industrial-scale projects. Proven success in Africa and remote sites.

8. Advantages

High efficiency: >95% gold recovery

Rapid deployment: minimal civil works

Portability: mobile units simplify relocation

Cost-effective: gravity-only design lowers operational costs

Gold wash plants provide a proven, gravity-based solution for gold recovery across scales. With modular, mobile setups and robust performance, they are ideal for both small-scale prospectors and industrial operations. Equipment adaptability for clay content and recovery needs ensures high yields and operational value. Let me know if you’d like help with specific models, process optimization, or sourcing options!

Magnetic Separation in Iron Ore Beneficiation

... [more]

No Next

Related Article

- Gold CIP Process: Principles, Flowsheet, Plant Design, and Best Practices

- What Is the Difference Between CIP and CIL Gold

- Gold Heap Leaching: Technical Insights, Operational Strategies, and Future Directions

- How is Gold Processed Step by Step

- Gold Ore Beneficiation: Advancing Efficiency and Sustainability

- Gold Mining Equipment Costs: A Down-to-Earth Guide

- Gold Ore Gravity Separation Equipment

- Comprehensive Analysis of CIP in Gold Processing

- Affordable Gold Ore Processing Practical Guide for Growing Enterprises

- The Gold Processing Plant Cost

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China